Publications

«ECO ships. Marketing teaser, albeit changing the shipping industry»

«ECO ships. Marketing teaser, albeit changing the shipping industry»

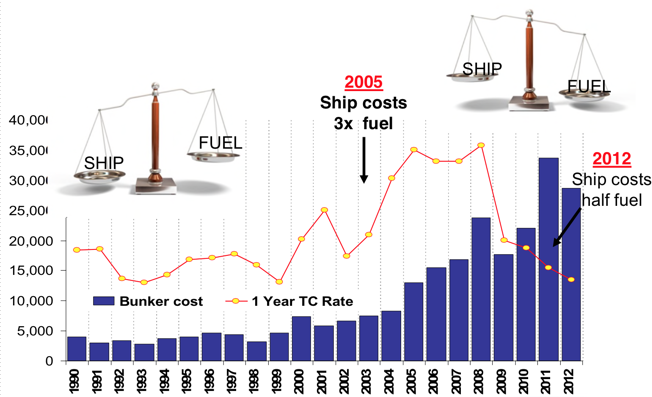

Economic Pressure

Based on Aframax tanker, 1 year TC rate and Rotterdam bunker price

Legislative Pressure

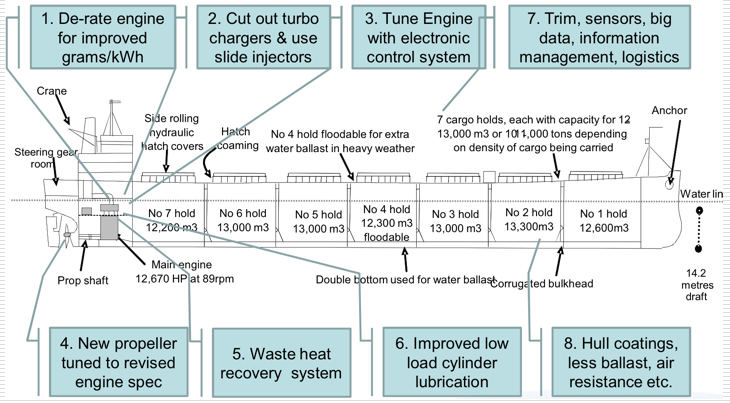

Increasing the performance of existing vessels

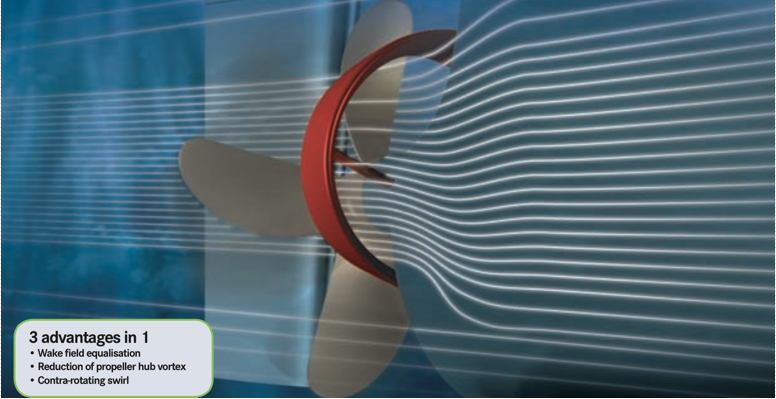

PROPULSION EFFICIENCY

The aim is to improve the propulsion efficiency by installing energy saving devices in way of the stern, in order to reduce the turbulence induced by the propeller, accelerate the hull wake and produce a net head thrust

PROPULSION EFFICIENCY

- Many devices on the market

- Different costs and benefits

- Effect of device will depend on hull:

- The devices typically recover lost energy

- If less energy is lost (through an efficient hull) then there is less energy to recover

- I.e. the effect of an energy saving device will be less on a hull which is designed for fuel efficiency (as opposed to deadweight optimized hull)

For NB’s: Focus should be to design the perfect hull, then consider to add devices as relevant.

PROPULSION EFFICIENCY

Becker Mewis Duct – most popular device on the market (more than 800 units sold)

Becker Mewis Duct

Becker Mewis Duct

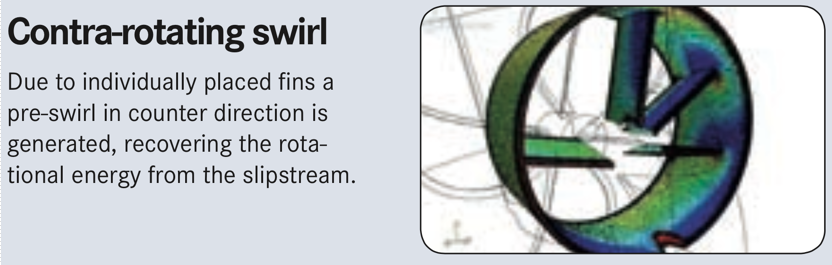

The Becker Mewis Duct harmonises and stabilises the flow and generates a pre-swirl to reduce the rotational losses in the propeller slipstream. The integrated fins have a stator effect by generating pre-swirl in counter direction of the propeller operation. This generates more thrust. The fins are asymmetrically profiled and arranged to generate a perfectly homogenous flow distribution.

Becker Mewis Duct Principles of energy savings

Becker Mewis Duct Principles of energy savings

Becker Mewis Duct Principles of energy savings

Main improvements for NEW vessels

- Electronically controlled engines

More efficient, especially for a wide range of loads/rpm - which enables low fuel consumptions at eco speed

- Long stroke engines

Improved efficiency of the engine

Lower RPM, enables a larger propeller, which has a higher efficiency

Megatrends

- Two-stroke diesel-engines

Reduced rpm

(incl. slow steaming)

Longer stroke

Less power / de-rated engines

(reduced ship speed)

- Gas engines / Dual fuel engines (two- and four strokes)

- Dual or multiple rating

Design of an engine in a way so that it can be rebuilt to different maximum continuous ratings

- Low friction lubricants

Hull Resistance Reduction

By upgrading existing AutoPilot units using software that incorporates the latest adaptive control technologies we achieve better maneuverability and optimum steering and consequently fuel savings in the range of 1.15%

Hull Monitoring Performance

Ship’s performance is monitored and in cases of deterioration underwater hull cleaning is carried out by divers.

Improving Power Efficiency

- Waste Heat Recovery Systems (WHRS)

For steam production from Diesel Generators Exhaust Gases

- LED Lighting Technology

For reducing the electrical energy consumption .

- De-rating of Main Engine and Propeller (potential energy savings 15%)

- Retrofitting of Flow meters

For more accurate measurement of bunkered and consumed fuels

- HFO Homogenizers

One before the HFO purifier for reducing the quantity of sludge and the other before Main Engine Inlet for homogenizing the hydrocarbon particles.

Waste Heat Recovery Economizer After Auxiliary Engines

The amount of the wasted thermal energy contained in A/E’s exhaust gases is capable of producing a considerable amount of steam which can contribute to the steam requirements when :

1. In port or in anchorage

2. Slow steaming

Evgeniy Dolgikh, 05.11.2014

download pdf back